#silicon dioxide sio2

Explore tagged Tumblr posts

Text

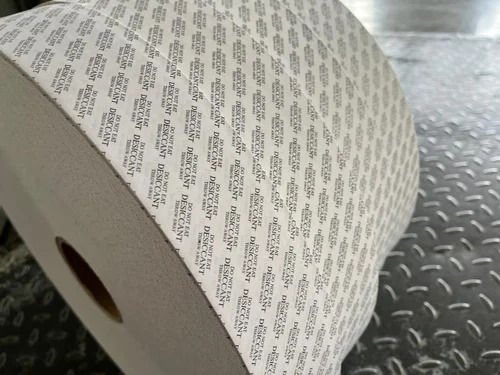

A common variarity of Silisiccatioid, found in a locker room at my job.

Silica Siccatio, known as the species Silisiccatioids and commonly referred to as "Silica Gel", is a species characterized by a rectangular or square-ish shape which is more or less flat, a thin exterior and a filling most commonly consisting of small, odorless white pearls, which can be felt through the outside membrane. These small spheres have been observed to consist of silicon dioxide (SiO2) and sometimes water or other forms of liquid. They have the remarkable ability to absorb moisture from the air around them and the outside membrane commonly consists of some form of paper, fabric or plastic which lets enough air pass through to enable this process. It is thought that the species somehow survives solely on this moisture, and have no need for a more nourishing diet.

These intriguing life forms are most commonly found in sealed boxes or other containers of food and other products, which is their natural habitat. They are a widespread species that have been discovered in different varieties all over the world. It is thought that the Sillisiccatioids have formed a symbiotic relationship with humans in which they help keep food and a wide variarity of other products from molding, spoiling and getting otherwise destroyed, by keeping the air moisture within the container low. In this way, Silisiccatioids get nourishment and protected living spaces while preventing sickness and waste of materials for the human race.

Silisiccatioids often display a variarity of patterns on their thin exterior, varying in color but having a common theme through all of them. They usually display text and in some cases, symbols, with messages such as "DO NOT EAT" and "THROW AWAY", a message which can be conveyed in many and sometimes multiple languages at once, though english is a common find. This is thought to serve as a protective strategy against humans, who might mistake them for another peice of food among the rest of the container's contents and consume them. Upon this, the internal beads of the Silisiccatioids have in fact also been shown to often have a toxic coating of cobalt chloride, a toxic element which causes nausea and vomiting upon consumption, as well as possibly further health risks. This provides an extra warning to other species against consumption. If you or a loved one has ingested a Silisiccatioid, please call the poison help line of your country.

It is not known why Silisiccatioids have evolved to only display exterior warnings comprehendable to humans, though many researchers suggest the reason to be that our species in particular lack the intelligence to refrain from such impulses.

The name Silisiccatioids, or Silica Siccatio, is originated from the name of their inside material, Silica, and the Latin word for "drying", Siccatio.

#silisiccatioids#silisiccatioid#silica siccatio#silica#silica gel#science#zoology#biology#fake zoology#cryptozoology

8 notes

·

View notes

Text

Today's rock/crystal is Amethyst.

Amethyst is the purple variety of the mineral quartz. Like other quartz, it is made up of silicon dioxide (SiO2) and has a hardness of 7. The purple color is due to traces of iron elements inside the amethyst.

The hardness of 7 means amethyst is moderately hard and is durable for daily use. Amethyst is considered as precious as diamond or ruby and is used in jewelry for royalty and high members of the church. Ancient civilisations believed that Amethyst would prevent intoxication.

#david kostyk#grishaverse rp#grishaverse#ask david kostyk#science facts with david kostyk#mineral facts with david kostyk

6 notes

·

View notes

Text

Day 8: Fire Agate

• Category: Oxide Mineral

• Formula: Silica (silicon dioxide, SiO2)

• Crystal System: Trigonal, Monoclinic

• Mohs Scale: 5-7

#anime#fanart#anime fanart#houseki no kuni original character#houseki no kuni oc#houseki no kuni fanart#houseki no kuni#land of the lustrous original character#land of the lustrous oc#land of the lustrous fanart#land of the lustrous#gemtober#gemtober 2024#headphonegirl21#headphonegirl21 art#digital art#artwork#fyp#fypシ#tumblr fyp#fypage#fypツ

5 notes

·

View notes

Text

Hibiscus: That’s cool. Are you into that stuff?

Citrine: Kind of? I think crystal healing is bullshit and an insult to people who need, like, actual medical care to survive. But I like the idea that every rock means something, and I have no issue with people who believe in that stuff as long as they're not hurting others. And I have a huge collection of amethyst geodes and clusters in my room, all from my dad, so maybe it rubbed off on me a little bit.

Hibiscus: You know, citrine and amethyst are both a macrocrystalline form of quartz.

Citrine: What now?

Hibiscus: You know, like silicon dioxide? SiO2? I took chemistry honors last year. It just means those stones are kind of molecularly similar, cut from the same cloth and all that.

Citrine: Damn I heard you were kind of a nerd, I didn’t believe it until now.

Hibiscus: Who says I am?? Was it Midna?

Citrine: *deflecting hard because it was definitely Midna* Sooo what’s your favorite flower? Like, if you had a kid, what would their name be?

Hibiscus: Uhh… I never really thought about it before.

Citrine: You don’t have a favorite flower?

#ts4 legacy#ts4 storytelling#ts4#berry sweet sims#pastel rainbowcy#dream bpr#dream gen 3#hibiscus dream#citrine shine

7 notes

·

View notes

Text

Moss Agate

Chalcedony, quartz family

Chemical Composition

SiO2

-a semi-precious gemstone formed from silicon dioxide, it is a type of chalcedony which has a green color in the stone with similar looks of moss.

-Calming

-Stress relief

-New beginnings

-Grounding/stability/emotional balance

-Helps move away from emotional drama

-Promotes abundance/good luck/Prosperity

-Promotes intuitively

-Peace

-Associated with Virgo

-Promotes new friendships

-Planet: Moon

-Element: Earth

-Confidence

-6.5- 7 Mohs

-Promotes Patience

-Protection of energy

-I personally love putting it in to help keep my plant's energies safe and help keep them alive and thriving.

Moss Agate Care

warm water/soapy water no harsh chemicals.

Use soft brushes and clothes to avoid scratches.

#beginner witch#witch tips#witchcraft#witchythings#witchyvibes#crystals#crystalmagic#witchblr#witchcraft community#green witchcraft#moss agate#study notes#study blog#good omens#spilled ink#heartstopper#crystal information#crystal community#magic#witchy blog#witchy#study aesthetic#studyblr#stunning#moss#moss ball#plantblr#plant community#plants#herbalism

13 notes

·

View notes

Text

Indigo blue sapphire (or) Padparadscha sapphire, spinel by b.g.stones / Fantasy cut tanzanite and amethyst Sapphire is a precious gemstone, a variety of the mineral corundum, consisting of aluminium oxide with trace amounts of elements such as iron, titanium, cobalt, lead, chromium, vanadium, magnesium, boron, and silicon. The name sapphire is derived via the Latin sapphirus from the Greek sappheiros, which referred to lapis lazuli.

Spinel's chemical composition is MgAl ₂O ₄ Tanzanite's chemical composition is Ca2Al3(SiO4)3(OH) Amethyst's chemical composition is silicon dioxide, SiO2

#crystal facet#crystal faceting#crystal#crystal gems#crystal gemstones#gems#gemstones#hidden gems#gemstone#crystals#beauty#beautiful#gorgeous#stunning#perfect#beauties#classy#elegance#elegant#style

3 notes

·

View notes

Text

"Molten sand glass" ain't white. If you want white glass you need to add something like antimony (semi-opaque white).

If you just melt sand and let it cool, it comes out yellow to black (depending on the impurities in the sand). Obsidian is a good example of what happens if you melt sand and let it cool, and it's often pretty transparent.

Powdered SiO2 will give you a clear and colourless crystal unless it's set funny (aka quartz). (I, personally, would say that calling "powdered silicon dioxide" sand is disingenuous at best.)

Also, clear and colourless glass absolutely predates the 15 th century. The Romans made it, using iron(3) oxide as a decolouring and clarifying agent. Some of it is in museums, and it is still colourless and (mostly) transparent.

#As for whether “white” is a colour#that's somewhat of a philosophical question along the lines of “is zero a number”#Sure it's got an RGB value#but it does NOT have a wavelength#there's no such thing as a “white photon”.

7K notes

·

View notes

Text

Why Choosing the Best Ceramic Coating Can Save Your Car’s Paint

Keeping your car looking new and shiny is something every car owner dreams of. But with time, the paint on your vehicle starts to fade, scratch, or even peel off due to dust, sunlight, rain, and pollution. This is where ceramic coating comes in. In this blog, we will explain why choosing the best ceramic coating is important and how it can save your car's paint for years to come.

What Is Ceramic Coating?

A Simple Explanation

Ceramic coating is a special type of liquid that is applied to the exterior of your car. Once it is applied and cured, it forms a hard, protective layer over the car's paint. This layer acts like a shield, protecting the surface from dust, water, UV rays, bird droppings, scratches, and other harmful elements.

Not Just a Wax

Many people confuse ceramic coating with regular wax or polish. But the truth is, ceramic coating lasts much longer and provides a higher level of protection than wax. While wax may last a few weeks, ceramic coating can protect your car for years.

Benefits of Choosing the Best Ceramic Coating

1. Long-Lasting Protection

The best ceramic coating can last for up to 2 to 5 years, depending on the product and how well you maintain your car. This long-lasting protection means you don't have to worry about waxing your car every month.

2. Shiny, Glossy Finish

A good ceramic coating gives your car a beautiful, deep gloss that makes it look brand new. This shine stays for a long time and gives your vehicle a premium appearance.

3. Easy to Clean

With ceramic coating, dirt and water slide off easily from the surface. This means less effort and time needed for cleaning. A simple wash is usually enough to keep your car looking clean.

4. Protection from UV Rays and Oxidation

Sunlight can cause your car’s paint to fade over time. Ceramic coating blocks harmful UV rays, keeping the paint color fresh and vibrant. It also helps in reducing oxidation, which can make your car's paint look dull and old.

5. Scratch Resistance

While no coating can make your car completely scratch-proof, the best ceramic coating can resist minor scratches and swirl marks that happen during regular washing or accidental touches.

6. Saves Money in the Long Run

Because ceramic coating is durable and long-lasting, you spend less on frequent polishing, waxing, or paint jobs. It is an investment that pays off over time.

How to Know Which Ceramic Coating Is the Best

1. Check the Ingredients

High-quality ceramic coatings are made with advanced nanotechnology and high percentages of SiO2 (Silicon Dioxide). The more SiO2, the better the protection.

2. Read Reviews and Ratings

Look for real customer reviews and expert opinions. Trusted brands will always have plenty of positive feedback and proven results.

3. Go with a Trusted Installer

Even the best ceramic coating will not give great results if it is not applied correctly. It’s always better to get the coating done by professionals who know what they are doing.

4. Warranty and Aftercare Support

Good ceramic coatings come with warranties that cover the product for years. Also, check if the installer offers aftercare support to help you maintain the coating.

Why Auto Nexus Recommends the Best Ceramic Coating

At Auto Nexus, we have worked with hundreds of vehicles and seen the difference that the best ceramic coating can make. Our team uses only premium-grade coatings that offer top-level protection, unmatched gloss, and a smooth finish.

Whether you have a brand-new car or an older one, we apply the coating with great care to ensure that your car gets the best shine and defense. Our goal is to help you keep your car looking its best, with minimum maintenance and maximum protection.

We have also seen how customers who choose quality ceramic coating at Auto Nexus end up saving money, time, and stress. They don’t need to polish or repaint their cars often and can enjoy that "new car" feel every day.

Common Myths About Ceramic Coating

Myth 1: Ceramic Coating Makes Your Car Scratch-Proof

Truth: It makes your car scratch-resistant, not scratch-proof. It can handle minor scratches but won’t protect from deep cuts or dents.

Myth 2: You Don’t Need to Wash Your Car After Coating

Truth: You still need to clean your car, but it will be much easier and faster since dirt and water don't stick as much.

Myth 3: Ceramic Coating is Too Expensive

Truth: While the upfront cost may be higher, the long-term savings on waxing, detailing, and paint correction make it a smart investment.

Tips to Maintain Ceramic Coating

Wash your car regularly using a pH-neutral shampoo.

Avoid automatic car washes with hard brushes.

Use microfiber cloths for drying.

Apply a ceramic coating booster every few months if needed.

Conclusion

Your car is not just a machine; it’s a part of your daily life and even your personality. Protecting its paint is not only about looks, but also about maintaining its value. Choosing the best ceramic coating ensures that your car stays protected, glossy, and easy to maintain.

If you’re looking for trusted results, professional service, and real value, Auto Nexus is here to help. Our experience, quality products, and customer care make us the go-to place for ceramic coating solutions.

Don't wait until your car's paint starts fading or peeling. Invest in the best ceramic coating today and enjoy a beautiful, protected ride for years to come!

0 notes

Text

What are the optical characteristics of fused silica glass tubes

The fused silica glass tube, as an inorganic glass material made of high-purity silicon dioxide (SiO2) through high-temperature melting and crystallization, has excellent optical properties. These characteristics have made it widely used in various fields such as optical instruments, optical communication, semiconductors, etc.

Luverre Quartz manufactures and sells a wide range of high quality quartz glass, including quartz tubes, quartz plates, quartz rods, quartz windows, quartz crucibles, quartz boats, quartz flanges, quartz beakers, quartz glass instruments, and more. We can meet all kinds of customized requirements for quartz glass products. https://www.luverrequartz.com/products.html Welcome to inquire about ordering

#quartzglasstube#quartztube#quartztubemanufacturer#quartzglasstubemanufacturer#quartztubesupplier#quartzglasstubesupplier#Customquartztube#Customquartzglasstube#quartztubeprice#quartzglasstubeprice#highpurityquartztube#highpurityquartzglasstube#ultrafinequartztube#ultrafinequartzglasstube#largequartztube#largequartzglasstube#fusedsilicaglasstube#Corrosionresistancetube#hightemperatureresistancetube#luverrequartz

0 notes

Text

Silica Sand Market Expansion Forecast and Competitive Insights 2032

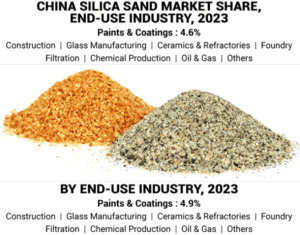

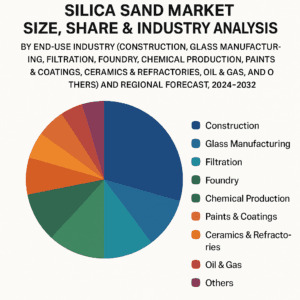

According to Fortune Business Insights™, the global silica sand market size was valued at USD 12.16 billion in 2023 and is projected to grow from USD 13.10 billion in 2024 to USD 23.70 billion by 2032, exhibiting a CAGR of 7.7% during the forecast period. Asia Pacific dominated the silica sand market with a market share of 29.28% in 2023. Moreover, the silica sand market size in the U.S. is projected to grow significantly, reaching an estimated value of USD 4.00 billion by 2032, driven by the increased production of oil and natural gas, which require silica sand for the fracking process. The rise can be attributed to the extensive range of applications, including inert chemical nature, high melting point, toughness, and others.

Silica sand (SiO2) is the finely crushed form of quartz. Industrial sand and gravel, often called quartz and silica sand, includes sand and gravel with high silicon dioxide content. It contains at least 95% SiO2 and less than 0.6% iron oxide. Sand that does not fulfill this criterion is considered regular sand.

This information is provided by Fortune Business Insights™ in its research report, titled “Silica Sand Market, 2024-2032”.

Get a Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/silica-sand-market-105302

List of Key Players Mentioned in the Report:

S. Silica (U.S.)

Sibelco (Belgium)

Covia Holdings LLC. (U.S.)

JFE Mineral & Alloy Company, Ltd. (Japan)

Quarzwerke GmbH (Germany)

PUM GROUP (Malaysia)

Badger Mining Corporation (S.)

Mitsubishi Corporation (Japan)

Preferred Sands (S.)

Aggregate Industries (U.K.)

Segments:

Construction Segment to Register Substantial Growth Owing to Escalated Product Adoption

On the basis of end-use industry, the market for silica sand is segregated into foundry, construction, paints & coatings, glass manufacturing, oil & gas, chemical production, ceramics & refractories, and others. The construction segment is slated to depict commendable expansion over the estimated period. The surge can be attributed to the growing product usage in the manufacturing of concrete and mortar.

Based on geography, the market is segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Report Coverage:

The report provides a comprehensive analysis of the major factors impelling the industry landscape across various regions. It further gives an insight into the prominent trends driving market expansion over the forecast period. Additional aspects comprise the significant steps taken by leading companies to gain a competitive edge.

Drivers and Restraints:

Market Value to Surge Owing to Escalating Demand from THE Glass Industry

One of the key factors propelling the silica sand market growth is the soaring product demand from the glass industry. The escalated product demand can be attributed to the low coefficient of thermal expansion and extreme thermal shock resistance. This helps in preventing any change in the material driven by sudden changes in temperature.

However, the market expansion could be hindered on account of various health hazards associated with the level and duration of crystalline silica exposure. Long-term exposure is associated with lung cancer, silicosis, chronic bronchitis, and numerous autoimmune diseases.

Regional Insights:

Asia Pacific to Emerge Prominent Due to Escalated Demand in Glass & Construction Activities

The Asia Pacific silica sand market share is estimated to register considerable expansion throughout the study period. The surge can be credited to increasing government expenditure on infrastructure development in the region.

The North America market is set to record lucrative growth over the analysis period. This is due to the growing production of natural gas and oil in the region. The process requires silica sand for the process of fracking.

Competitive Landscape:

Leading Players Undertake Research Activities to Develop New Products

Major silica sand companies are undertaking research activities for the development of various products. These industry players are also formulating and implementing a series of strategic initiatives for strengthening their position in the market. These include mergers, formation of alliances, acquisitions, and others. Besides, some companies are participating in trade fairs for enhancing their business prospects.

To know more about this market, please visit: https://www.fortunebusinessinsights.com/silica-sand-market-105302

Key Industry Development:

July 2022- Allup Silica Ltd. enhanced its resources for a silica sand project based in Western Australia. The initiative is called “Sparkler A Silica Sands Exploration Project”.

July 2022- Finnish Vatajankoski and Polar Night Energy presented the first fully functional "sand battery" capable of storing green electricity, which provides a low-emission and low-cost way to store renewable energy.

0 notes

Text

So yes, you can put 4 towers around the city. You might need a few more, but those towers can vacuum in sand removing it from the atmosphere, and preventing the city from getting hit with a sandstorm... oh, they're looking to do something like this. In Dubai see the video...

But knowing the different elements of sand you can break them down into the different elements and use those elements to make many things...

Scientific.Net

https://www.scientific.net

Minerals Characterization of Magnetic and Non ...

by N Khuzaima · 2018 · Cited by 7 — The most commonly occurring sand mineral deposits are ilmenite, rutile, magnetite, cassiterite, monazite, tourmaline, zircon, kyanite, silimanite, and garnet.

CK-12 Foundation

https://www.ck12.org

The best way to separate a mixture of iron filings and sand is using ...

Iron filings will be attracted to a magnet due to iron's magnetic property, and sand will be left behind as it is non-magnetic.

The Royal Society of Chemistry

https://periodic-table.rsc.org

Silicon - Element information, properties and uses

Sand (silicon dioxide or silica) and clay (aluminium silicate) are used to ... The tendency of an atom to attract electrons towards itself,

Magnetite, an iron oxide mineral, is the element in sand that attracts a magnet. It's a naturally occurring iron ore found in many rocks and is a significant component of black sand.

Explanation:

Magnetite and Magnets:

Magnetite is a mineral that has strong magnetic properties, meaning it is attracted to magnets.

Black Sand:

Black sand often contains magnetite, which is why it can appear magnetic.

Iron Oxide:

Magnetite is an iron oxide, and the iron within it is what makes it magnetic.

Separating Magnetic Sand:

If you have a mixture of sand and iron filings, you can use a magnet to separate the magnetic sand (containing magnetite) from the non-magnetic sand.

Common Sand Composition:

While magnetite is a component of black sand and can be attracted to magnets, sand generally consists of silica (SiO2), which is not magnetic.

Magnetic Sand - YouTube

Jun 2, 2016 — is because there's a lot of sand. well every beach has sand. but aside from building castles you can actually do something pretty cool and you're goi...

YouTube ·

Jet Man

So to make this work to attract the sand to prevent the sandstorm from hitting the city, you would use magnets to attract the magnetic particles, and then you would use these electrical fields to get the rest of the nonmagnetic particles.

Non-magnetic particles are not directly attracted by magnets in the same way magnetic materials like iron are. Instead, they can be attracted to or repelled by a magnetic field through phenomena like paramagnetism or diamagnetism, respectively. Additionally, electrostatic forces can also play a role in attracting certain non-magnetic particles.

Here's a more detailed explanation:

Diamagnetism:

In diamagnetic materials, all electrons are paired, and they weakly repel magnetic fields. Examples include materials like helium, bismuth, graphite, and water.

Paramagnetism:

In paramagnetic materials, some electrons are unpaired, leading to a weak attraction to magnetic fields. These materials are usually more attracted to stronger magnetic fields.

Electrostatic Forces:

Electrostatic attraction or repulsion can also influence the interaction of non-magnetic particles with a magnet. For example, a charged plastic brush can be attracted to a charged magnet due to electrostatic forces.

Magnetic Shielding:

While it's not possible to completely block a magnetic field, materials like steel can be used to redirect magnetic field lines, effectively shielding objects from the magnetic field.

Are All Metals Magnetic or Attracted by Magnets

Jun 15, 2021 — The other materials, thought of as non-magnetic, actually have extremely weak interactions with magnetic fields (usually barely perceivable) but the...

Eclipse Magnetics

youtube

1 note

·

View note

Text

India Industrial Silica Market Research Report 2024(Status and Outlook)

Market Size

The India industrial silica market is projected to experience significant growth, expanding from USD X billion in 2024 to USD X billion by 2030. This growth is expected to occur at a Compound Annual Growth Rate (CAGR) of X% during the forecast period of 2024 to 2030.

The demand for industrial silica in India is bolstered by the rapid industrialization and urbanization trends, particularly in the manufacturing, construction, and automotive sectors.

Historically, the market size for industrial silica has shown consistent growth, driven by the increased demand for construction materials and the growing electronics market in India. The market has also benefited from government initiatives aimed at promoting industrial production, including the "Make in India" initiative and infrastructure development programs.

Industrial silica is a high-purity form of silicon dioxide (SiO2) that is widely used in various industrial applications. This versatile mineral is primarily sourced from sand, which is refined to produce different types of silica for specialized uses. In the context of the industrial silica market in India, silica is predominantly used in the production of glass, ceramics, casting, and in various chemical processes. Other notable uses include its role as a filler material in the production of rubber, plastics, and paints.

Download & Explore the Report

The market for industrial silica in India is characterized by its diverse applications across multiple industries. These include manufacturing, automotive, construction, and electronics, where the mineral plays an essential role due to its physical properties such as high melting point, low thermal expansion, and resistance to chemicals.

India Industrial Silica Market: Market Segment Analysis

The India industrial silica market can be broken down into various segments based on different criteria such as application, type, and region. A deeper understanding of these segments provides valuable insights into the market dynamics and potential growth opportunities. This section will explore the segmentation of the India industrial silica market, covering key aspects like application and type.

Market Dynamics:

Drivers

The growth of the industrial silica market in India is primarily driven by several key factors:

Industrialization and Urbanization: With the rapid industrialization in India, particularly in sectors like construction, automotive, and electronics, the demand for high-quality industrial silica is on the rise.

Growth in Construction Industry: As India continues to experience urban growth, the need for industrial silica in the production of glass, ceramics, and other construction materials is increasing.

Demand from the Automotive Industry: The automotive sector's growth is driving demand for industrial silica, especially in the production of tires, lubricants, and plastic components.

Technological Advancements: Advances in silica processing techniques, including new methods to produce high-purity silica, are boosting its demand in specialized applications such as electronics and solar panel manufacturing.

Restraints

Despite the promising growth, the industrial silica market in India faces a few challenges:

Price Fluctuations: The prices of raw silica and its refined forms can be volatile due to fluctuations in global supply chains, particularly for sand and silica-related materials.

Environmental Concerns: The extraction of silica sand can lead to environmental degradation, including water scarcity, land erosion, and habitat destruction, which may result in regulatory challenges for mining operations.

Competition from Substitute Materials: The availability of alternative materials like synthetic silica and other industrial fillers can restrain the growth of the market.

Opportunities

The India industrial silica market presents several opportunities for growth:

Emerging Applications in Solar Energy: With the growing demand for renewable energy, especially solar power, there is an increasing need for industrial silica in the production of solar panels.

Expanding Electronics Industry: As India becomes a global hub for electronics manufacturing, the demand for industrial silica in components such as semiconductors and optical fibers is expected to grow.

Increasing Investment in Infrastructure: Ongoing government investment in infrastructure projects, including smart cities, highways, and residential complexes, provides a significant growth opportunity for the industrial silica market.

Challenges

The market also faces challenges such as:

Regulatory Hurdles: Government regulations regarding mining and extraction processes can pose challenges for companies involved in silica production.

Supply Chain Disruptions: Global supply chain disruptions, such as those caused by the COVID-19 pandemic, can impact the availability and price stability of industrial silica in India.

Market Segmentation (by Application)

The industrial silica market in India can be segmented based on its various applications, which include:

Glass Manufacturing

Foundry (Casting)

Construction (Concrete, Mortar, etc.)

Electronics (Semiconductors, Optical Fiber)

Automotive (Tires, Lubricants)

Rubber and Plastics

Market Segmentation (by Type)

The market can also be segmented based on the type of industrial silica:

High Purity Silica

Silica Sand

Fumed Silica

Precipitated Silica

Download & Explore the Report

Key Companies

Some of the key players in the India industrial silica market include:

Company A – Leading supplier of industrial silica with a focus on sustainability and product innovation.

Company B – Renowned for its strong presence in the glass manufacturing sector.

Company C – A key player in the automotive and electronics sectors.

Geographic Segmentation

India's industrial silica market is geographically segmented into several regions, including:

North India

West India

South India

East India

Regional Analysis:

India's industrial silica market shows varied demand trends across different regions:

Northern India: The region, which includes key industrial hubs like Delhi, Haryana, and Punjab, has a growing demand for industrial silica, especially in the manufacturing of glass and ceramics.

Western India: States like Maharashtra and Gujarat have significant demand for silica due to the strong presence of the automotive and chemical industries.

Southern India: Known for its expanding electronics and solar energy sectors, southern states like Tamil Nadu, Karnataka, and Andhra Pradesh are witnessing growing demand for industrial silica in the manufacturing of electronic components and solar panels.

Eastern India: While the eastern region has relatively lower demand compared to other regions, it is witnessing steady growth, particularly in the construction sector.

Competitor Analysis:

The India industrial silica market is highly competitive, with numerous global and domestic players operating in the space. Key competitors include:

Silica Company A: A leading player known for its high-purity industrial silica used in a variety of applications, including glass manufacturing and electronics.

Silica Company B: A major supplier with a strong focus on sustainable mining practices and eco-friendly silica products.

Silica Company C: Known for its extensive distribution network and competitive pricing, serving a range of industries, including automotive and construction.

These companies utilize strategies such as product differentiation, technological advancements, and partnerships to maintain their competitive edge in the market. They also focus on expanding their product portfolios and enhancing their customer relationships to secure long-term growth.

FAQ Section:

1. What is the current market size of the Industrial Silica market in India?

The India industrial silica market is projected to grow from USD X billion in 2024 to USD X billion by 2030, at a CAGR of X%.

2. Which are the key companies operating in the Industrial Silica market?

Key players in the India industrial silica market include Company A, Company B, and Company C, among others.

3. What are the key growth drivers in the Industrial Silica market?

The key growth drivers include industrialization, growth in construction and automotive sectors, demand from electronics manufacturing, and technological advancements in silica processing.

4. Which regions dominate the Industrial Silica market?

Western and Southern India dominate the industrial silica market due to strong industries like automotive, electronics, and construction in these regions.

5. What are the emerging trends in the Industrial Silica market?

Emerging trends include increased demand from the solar energy sector and the growing electronics industry in India.

Download & Explore the Report

0 notes

Text

Silica Gel Packaging Material

In today's competitive market, product safety during storage and transit is non-negotiable. One of the most trusted and effective solutions to protect your valuable goods from moisture damage is Silica Gel Packaging Material. Whether it's electronics, pharmaceuticals, leather, garments, or food products, silica gel plays a crucial role in maintaining product quality by keeping moisture at bay.

What is Silica Gel Packaging Material?

Silica Gel is a highly porous and granular form of silicon dioxide (SiO2) that can absorb moisture up to 40% of its own weight. It is commonly used as a desiccant (moisture absorber) in industries to prevent rust, corrosion, fungus, and spoilage caused by humidity.

It is usually available in small sachets, pouches, or packets made from non-woven fabric, paper, or Tyvek, making it easy to place inside boxes, containers, or packaging of products.

Features of Silica Gel Packaging Material

✅ Superior Moisture Absorption Silica gel can absorb moisture effectively, preventing damage to sensitive products.

✅ Non-Toxic and Eco-Friendly It is non-toxic, chemically stable, and does not react with other materials, making it safe for most industries.

✅ Available in Multiple Sizes From small 1-gram sachets to large 1 kg bags, silica gel packets are available in various sizes depending on the product's moisture protection needs.

✅ Clear Indication with Indicator Silica Gel Indicator silica gel changes color when it has absorbed moisture, making it easy to know when it needs replacement.

✅ Cost-Effective Protection Compared to other moisture-control options, silica gel offers a long-lasting and budget-friendly solution.

Applications of Silica Gel Packaging Material

Silica Gel is widely used in various sectors:

Electronics: Protects circuit boards, devices, and gadgets from moisture.

Pharmaceuticals: Keeps medicines dry and free from moisture-induced damage.

Leather Goods: Prevents fungus and mold formation on shoes, bags, and leather articles.

Garments and Textiles: Keeps clothes and fabrics fresh during shipping and storage.

Food Products: Absorbs moisture in packaged snacks, spices, and dry fruits (food-grade silica gel only).

Automotive: Protects machinery parts, metal components, and tools from rusting.

Why Choose Our Silica Gel Packaging Material?

At [Your Company Name], we manufacture and supply high-quality, customizable Silica Gel Packaging Materials designed to suit your industry needs. We ensure:

Consistent quality and moisture absorption capacity

Custom printing and private labeling options

Bulk availability at competitive prices

Fast and reliable delivery

Available Sizes of Silica Gel Sachets

SizeAbsorption CapacityRecommended Use1 gmSmall electronic items, watchesRetail packs5 gmLeather wallets, pouchesSmall boxes10 gmPharmaceuticals, textilesMedium cartons50 gmGarments, shoes, electronicsLarge cartons100 gm & aboveMachinery, automotive partsExport & heavy packaging

FAQs About Silica Gel Packaging Material

Q1: Is silica gel reusable? Yes, some types of silica gel can be regenerated by heating and reused.

Q2: Is silica gel safe for food? Only food-grade silica gel is safe for food contact. Always check labeling.

Q3: How long does silica gel last? Depending on humidity levels, silica gel can last from a few weeks to several months.

Q4: Can I customize the silica gel sachets? Yes, we provide customizable sachets with printing and size variations.

0 notes

Text

Best Ceramic Coating for Cars: How to Choose the Right One 🚗✨

Choosing the right ceramic coating for your car can be tricky with so many options available. Whether you’re looking for budget-friendly protection or long-lasting durability, here’s what to consider when picking the best ceramic coating for your vehicle.

1. Durability: How Long Do You Want It to Last?

🔹 Entry-Level Coating – Lasts 6 months to 1 year (Ideal for DIY users). 🔹 Mid-Grade Coating – Lasts 2-3 years (Better durability with proper maintenance). 🔹 Professional-Grade Coating – Lasts 5+ years (Best protection, applied by experts).

✅ Best Choice: Go for a 3-5 year coating if you want long-term value.

2. Hydrophobic Properties: Water & Dirt Repellency

🔹 Look for coatings with high water beading and sheeting effects. 🔹 Hydrophobic coatings make cleaning easier by repelling dirt, water, and contaminants.

✅ Best Choice: Coatings with SiO2 (Silicon Dioxide) above 80% provide excellent water repellency.

3. Scratch & UV Protection

🔹 Higher SiO2 or Graphene-based coatings offer better resistance against minor scratches. 🔹 UV protection prevents fading and oxidation from sun exposure.

✅ Best Choice: Graphene-infused ceramic coatings offer stronger heat and scratch resistance.

4. Ease of Application: DIY vs. Professional

🔹 DIY Coatings – Easier to apply but require frequent reapplication. 🔹 Professional Coatings – Need expert application but offer better bonding and durability.

✅ Best Choice: If you want long-term, hassle-free protection, choose a professional ceramic coating.

Final Verdict: Which Ceramic Coating is Right for You?

✔ If you want affordable, short-term protection, go for a DIY ceramic spray. ✔ If you prefer long-lasting, high-gloss protection, choose a professional-grade ceramic coating.

🔹 Want expert ceramic coating for ultimate protection? Get it done at Doctors of Detailing! 🚘✨

0 notes

Text

Introduction

When it comes to premium vehicle protection, car enthusiasts are constantly on the lookout for the latest and most effective solutions. One of the most advanced technologies in the industry today is Graphene Coating. It offers superior protection, durability, and hydrophobic properties compared to traditional ceramic coatings. At Falcon Car Detailing Studio, we specialize in applying high-quality graphene coatings to ensure your car remains in pristine condition for years to come.

In this blog, we’ll explore what graphene coating is, its benefits, pricing, and why Falcon Car Detailing Studio is your best choice for graphene coating applications.

What is Graphene Coating?

Graphene coating is an advanced liquid polymer infused with graphene, a single layer of carbon atoms arranged in a hexagonal lattice. Known for being the strongest and thinnest material on Earth, graphene enhances traditional ceramic coatings by improving their chemical resistance, durability, and performance.

Unlike conventional ceramic coatings, which primarily rely on silicon dioxide (SiO2), graphene coatings incorporate graphene nanoparticles, making them more flexible, heat-resistant, and hydrophobic. This results in a highly effective shield against environmental contaminants, water spots, and oxidation.

Benefits of Graphene Coating

Graphene coating provides numerous advantages over traditional car protection solutions. Below are some of the key benefits:

1. Unmatched Durability

Graphene is one of the strongest materials in existence, making graphene coatings extremely durable. When applied correctly, graphene coatings can last 5 to 7 years, significantly outlasting traditional waxes and even some ceramic coatings.

2. Superior Hydrophobic Properties

One of the standout features of graphene coating is its exceptional water-repelling ability. Water beads up and rolls off effortlessly, reducing the chances of water spots and mineral deposits forming on your vehicle’s surface. This self-cleaning effect makes maintenance easier and keeps your car looking new.

3. Resistance to Heat & UV Damage

Graphene coatings offer excellent heat dissipation, preventing excessive heat buildup on your car’s surface. This reduces the risk of paint damage from prolonged sun exposure. It also helps in reducing water-spot etching, which is common with ceramic coatings.

4. Enhanced Gloss & Deep Shine

A graphene coating enhances your vehicle’s paintwork, providing a mirror-like finish with deep, rich gloss. The result is a showroom-quality shine that lasts for years, keeping your car looking as good as new.

5. Anti-Static & Less Dust Accumulation

Unlike traditional ceramic coatings, graphene coatings have anti-static properties, which means they attract less dust and dirt. Your car remains cleaner for longer, reducing the need for frequent washes and maintenance.

6. Scratch & Chemical Resistance

Graphene coatings provide a tough, protective barrier against minor scratches, swirl marks, bird droppings, tree sap, and harsh chemicals. This keeps your car’s paint in top condition while minimizing damage from environmental contaminants.

7. Easy Maintenance & Reduced Cleaning Time

Thanks to its hydrophobic nature and anti-static properties, graphene-coated cars require less frequent washing. When you do wash your car, dirt and grime come off easily, saving you time and effort.

Graphene Coating Price: Is It Worth the Investment?

The cost of graphene coating varies depending on the size of your vehicle and the level of detailing required. On average, professional graphene coating services range from $500 to $2,000. While the initial investment may seem high, it provides long-term protection, reducing the need for frequent waxing, polishing, and repainting.

At Falcon Car Detailing Studio, we offer competitive pricing with top-tier graphene coating solutions, ensuring that you get the best value for your money.

Graphene Coating vs. Ceramic Coating: Which One Should You Choose?

Many car owners wonder whether they should opt for graphene or ceramic coating. Here’s a quick comparison to help you decide:

Overall, graphene coating offers superior protection, longevity, and hydrophobicity compared to ceramic coatings. If you want the best possible protection for your car, graphene is the way to go.

How to Apply Graphene Coating for Maximum Effectiveness

For optimal results, graphene coating should be applied by professionals. Here’s a step-by-step process followed at Falcon Car Detailing Studio:

https://www.instagram.com/falcon_cardetailingstudio

Step 1: Thorough Cleaning & Decontamination

Step 2: Paint Correction (If Necessary)

If the paint has swirl marks or minor scratches, we perform a paint correction to achieve a flawless finish before applying the coating.

Step 3: Application of Graphene Coating

The graphene coating is carefully applied in thin layers, ensuring even coverage across the entire vehicle.

Step 4: Curing Process

The coating needs 24 to 48 hours to cure properly, during which the car should not be exposed to water or extreme weather conditions.

Step 5: Final Inspection & Delivery

Once the coating is fully cured, we conduct a final inspection and deliver the car with a stunning, long-lasting shine.

Why Choose Falcon Car Detailing Studio for Graphene Coating?

At Falcon Car Detailing Studio, we specialize in high-quality graphene coating services tailored to meet the needs of car enthusiasts and daily drivers alike. Here’s why you should choose us:

Conclusion

Graphene coating is a game-changer in the world of car protection, offering unmatched durability, superior hydrophobicity, and incredible gloss. If you’re looking for the ultimate way to protect and enhance your vehicle, Falcon Car Detailing Studio is here to help.

Contact us today to book an appointment and give your car the protection it deserves!

#Car Detailing Studio#Best Car Detailing In Bangalore#car graphen coating bangalore#PPF#PPF In bangalore#Ceramic coating bangalore#falcon car detailing studio

0 notes

Text

The Ultimate Guide to Ceramic Coating for Cars: Benefits, Process, and Maintenance

In the quest for the perfect shine and protection for your vehicle, ceramic coating has emerged as a revolutionary solution. This advanced method offers long-lasting protection, a glossy finish, and minimal maintenance, making it a favorite among car enthusiasts and everyday drivers alike. If you're considering ceramic coating for car, this guide will help you understand what it is, its benefits, the application process, and how to maintain it for optimal results.

What Is Ceramic Coating?

Ceramic coating is a liquid polymer applied to the exterior of a car. Once cured, it creates a chemical bond with the factory paint, forming a protective layer that repels contaminants and enhances the vehicle's appearance. Unlike wax or sealants, ceramic coating is semi-permanent, lasting several years when applied and maintained correctly.

The main component of ceramic coating is silicon dioxide (SiO2), often derived from natural sources like quartz or sand. This material provides the hard, glass-like finish that is resistant to UV rays, dirt, and minor scratches.

Key Benefits of Ceramic Coating

Enhanced Paint Protection Ceramic coating acts as a shield against environmental contaminants such as bird droppings, tree sap, acid rain, and road grime. Its hydrophobic properties make cleaning your car a breeze, as water and dirt slide off easily.

UV and Oxidation Resistance Prolonged exposure to the sun can lead to paint fading and oxidation. Ceramic coating offers UV resistance, ensuring your car’s color remains vibrant over time.

Glossy, Mirror-Like Finish The high-gloss finish provided by ceramic coating elevates your car's appearance, giving it a showroom-like shine that is hard to achieve with other products.

Longevity While wax and sealants need frequent reapplication, a professionally applied ceramic coating can last anywhere from two to five years, depending on the quality of the product and proper care.

Cost-Effective in the Long Run: Though the initial application can be expensive, ceramic coating reduces the need for regular waxing, polishing, and extensive cleaning, saving money over time.

The Ceramic Coating Application Process

Applying ceramic coating is a meticulous process that requires precision and patience. While you can opt for DIY kits, professional application ensures the best results. Here’s an overview of the steps involved:

Thorough Cleaning The car must be thoroughly washed to remove all dirt, grease, and contaminants. This step often includes clay bar treatment to eliminate embedded particles.

Paint Correction Any scratches, swirl marks, or imperfections in the paint are polished out to create a smooth surface. Ceramic coating cannot hide flaws; it only enhances them if left untreated.

Application of the Coating The ceramic coating is carefully applied in small sections using a specialized applicator. The coating is then buffed to ensure an even layer.

Curing The coating needs time to cure, which can take 24 to 48 hours. During this period, the car should be kept in a clean and dry environment.

Maintaining Ceramic Coating

To get the most out of your ceramic coating, regular maintenance is essential. Here are some tips to keep your car looking flawless:

Regular Washing Wash your car every two weeks using a pH-neutral car shampoo. Avoid harsh chemicals or automatic car washes with abrasive brushes that can damage the coating.

Use the Two-Bucket Method Prevent scratches by using one bucket for soapy water and another for rinsing your wash mitt. This reduces the chances of dirt being reapplied to the car.

Avoid Harsh Cleaning Tools Stick to microfiber towels and soft sponges for cleaning. Avoid abrasive materials that could wear down the coating.

Periodic Top-Up Products Some ceramic coatings benefit from maintenance sprays designed to enhance their hydrophobic and glossy properties.

Inspect for Wear Over time, high-use areas like door handles and mirrors may show signs of wear. Consider reapplying the coating to these spots as needed.

Is Ceramic Coating Worth It?

For those who value their vehicle’s appearance and want long-term protection, ceramic coating is a worthwhile investment. It saves time on maintenance, offers superior protection, and keeps your car looking its best for years. Whether you drive a luxury vehicle or a daily commuter, ceramic coating provides benefits that are hard to match.

In conclusion, ceramic coating is more than just a cosmetic upgrade; it's a robust protective solution that enhances your car's longevity and aesthetic appeal. With proper application and care, your vehicle will not only look stunning but also be shielded from the elements for years to come.

Visit: https://morleycarwash.com.au/ceramic-coating-car/

0 notes